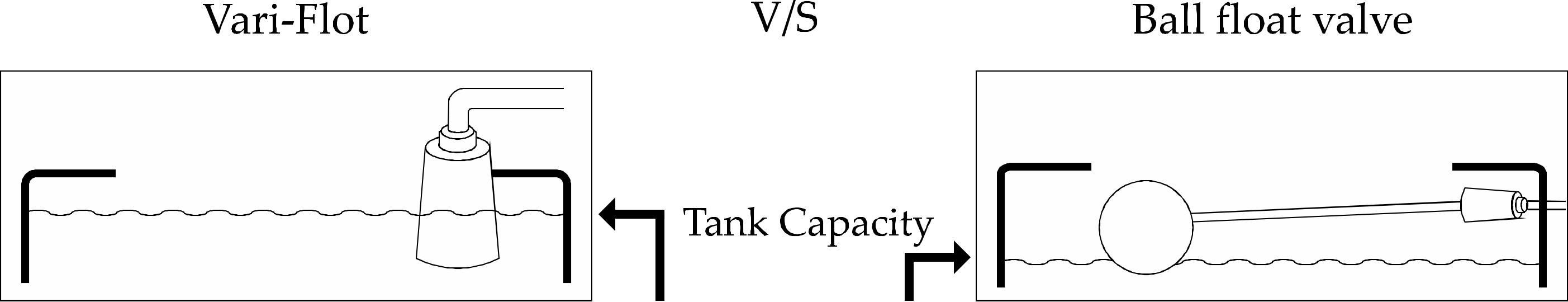

The Vari-Flot is a Diaphragm operated Float Valve used to prevent tank overflows. This new generation tank level controller automatically turns off the supply to the tank once it gets filled up and restarts supply as the water level drops. This is the most compact, long life float valve which makes the old ball cock Float Valve look obsolete.

As the water level rises above the base of the Vari-Flot the float rises up and activates the diaphragm which uses the water pressure itself to turn off the valve and stop inflow of water completely.

The Vari-Flot is most ideal for any tank where water supply needs to be automatically shut off. Some typical examples are…

1) Use plumbers Teflon tape on threads of pipe. DO NOT USE PIPE CPMPOUND.

2) Screw the Vari-Flot on the pipe thread. Hand tighten only. Ensure it is mounted stably. Vari-Flot will not work if it is not secured properly in its place.

3) Turn supply on and allow water to fill in.

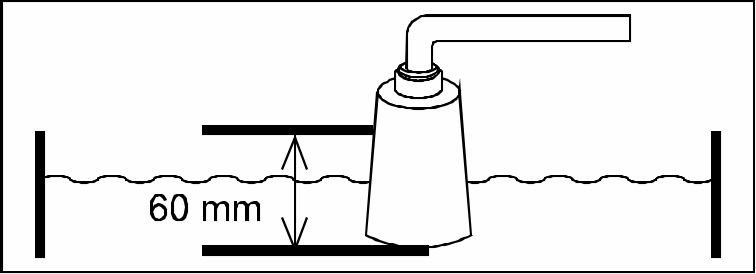

4) Vari-Flot will shut off when water level will reach 35-50mm ( depending upon pressure) above its base level. Note – there will be a short delay in shut-off for the first time.

5) Can be installed only on vertical pipe.

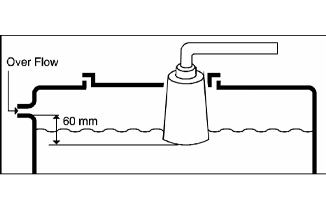

6) In case of tanks with overflow pipe ensure that the Vari-Flot is positioned such that water flow stops well below over-flow level considering possibilities of turbulence also to prevent water spillage.

7) Though designed for extremely long life, the diaphragm operated Vari-Flot needs dirt free water for smooth functioning. Although is it very easy to remove the internals and clean the dirt that chokes inside the holes of stem and pin etc. it is highly recommended to install the EasyClean Strainers with 200 to 400 microns filtration capacities. These will reduce downtime and maintenance of cleaning the Varo-Flot frequently.

Cut a hole in lid of tank or ceiling of tank matching the diameter of Vari-Flot.

Screw the Vari-Flot on to the pipe thread. Ensurethat the base of Vari-Flot in about 60mm below the overflow pipe ( max tank level) as in previous sketch

OR

Pass the pipe in to the tank preferably near the lid. Screw in the Vari- Flot on to pipe thread

OR

Install the Vari-Flot in the space of the lid and cut out and arc on the lid of the tank so that if fits around the Vari-Flot.

Install Vari – Flot directly on top of tank. Ensure that base of float is about 60mm below the top level of tank.

Where larger diameter pipes are there, a manifold as shown in sketch can be created and matching no. of Vari-Flots can be used to control the flow. General thumb rule for deciding qty of Vari-Flots is to match the cross section area “A” of discharge pipe (A=πr^2) with the total area of flow of all Vari-Flots put together (area of each Vari-Flot can be considered as 176mm2) or alternatively check if flow rate is sufficient from them. Also Make sure that they are installed at same horizontal level.

| Connection Size | : | 15mm (1/2"). # | ||||

| End Connection | : | Female Thread | ||||

| Operating Pressure | : | 0.3 kg/cm2 (3 meters) to 4.5 kg/cm2 (45 meters) | ||||

| Flow Rate | : | Approximately 80% of flow supplied to valve | ||||

| Max Fluid Temp. | : | 90oC | ||||

| Dimensions (in mm) | : | Height (H) | 128 |  |

||

| Dimensions (in mm) | 72 | |||||

# Use manifold with multiple Vari-Flots for larger diameter Pipes as explained in APPLICATIONS section